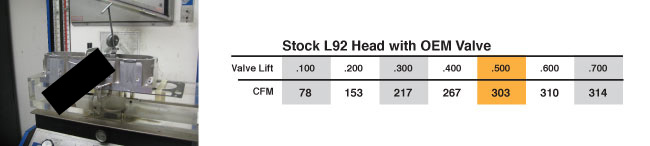

If you can't outflow us you will never outrun us! At VR we flow test every product in true dynamic, real world and simulated dynamic configurations. We do this to find an induction system's true limitations. This is why we flow every component as it would be installed on the vehicle. This provides the closest representation of real world flow in a controlled environment. We never flow components by themselves because an induction system is just that... a "SYSTEM" not a sub component. These are flow numbers from some popular brands for the world to see. We flow tested these systems all the way through the cylinder head, because if it does not show up in the head it is simply not there. Once you see the results, you'll be the judge |

|

|

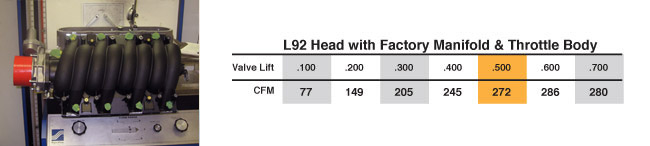

You can see how much the OEM manifold hurts airflow! (we are fixing this too)

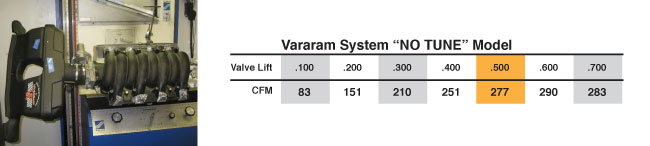

The VR EXCEEDS OEM flow requirements by using a special high flow air-horn/MAF

design that is located directly in front of the throttle body. This location offers the maximum increase

in aerodynamic efficiency for maximum airflow. The new elliptical neck and rifled barrel design offer

phenomenal low Lift/RPM performance that is simply untouchable.

Shrouding was removed for increased flow.

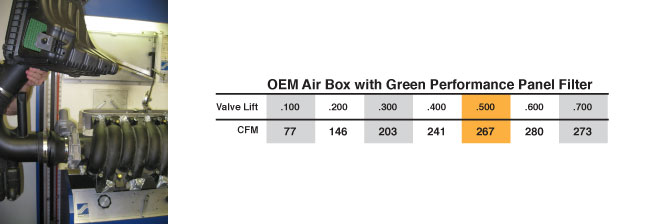

OEM stock air-box, with a GREEN HIGH PERFORMANCE replacement panel filter.

Here is the surprise of the group for all to see. With nothing but a Green High Performance filter(outflows K&N by 20%) this $65 filter allowed the OEM box to nearly match the best of the

rest for a fraction of their cost and without the heat soak penalties of some of the systems.

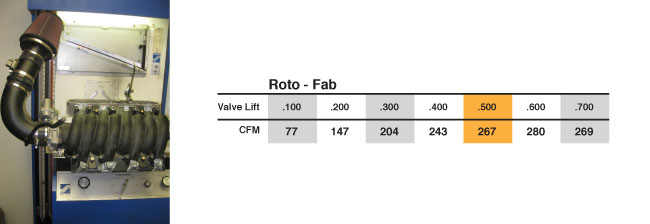

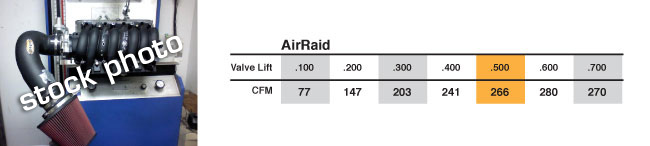

We helped this one along by removing their shrouding when installed in the car for max flow performance.

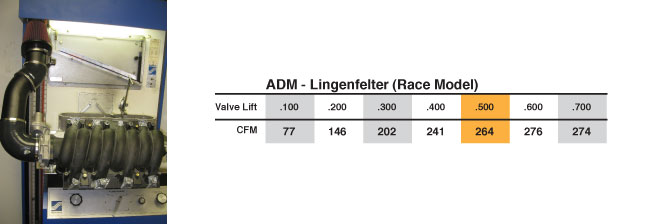

Again we removed the metal shrouding for additional flow.

So how much HP is one CFM per cylinder worth? |

Here is a list of other intakes that did not make it into the (in no particular order) |

| Don't spend thousands of $$$ and then go cheap on the intake system! As you can see it will cost you HP Do it right the first time, buy a VaraRam and watch the competition in your mirror. |

* Test results may vary in a different environment, however these are the results frim this particular test.