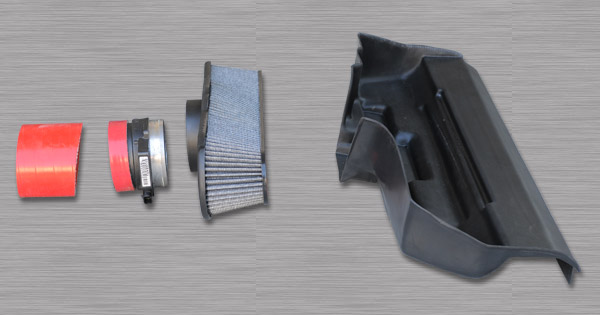

Pontiac GTO/Holden, Cold Air system |

||

|

||

|

||

This system has been a long time coming for the GTO/Holden owners. We would like to thank all the GTO forum members who tested and ran our prototype mules for the last few months as we gathered data from their vehicles! We would also like to thank them for being so patient. We test, re-test and test again to find every possible amount of power while reaching our mileage goals of 12,000 miles without issue.

|

||

|

||

|

||

(on to the system) We accomplished this goal through intensive on road and track testing which revealed the shortcomings of every other aftermarket system we tested from US and Australian manufacturers. They “ALL” suffered from heat soak- the Holden /GTO has a sealed engine compartment. This allows very little air in or out, so these cars run HOT naturally, let alone if the motor is built or supercharged! (Creating more heat, remember, horsepower is heat!) We tested kits that used many configurations, some went over the radiator some to the fender and others sealed to the hood, ALL of them heat soaked the mass airflow meter and air box assembly. THE VR remedy- At VR we only design our products for the “REAL WORLD” not a static test, because U don’t win races standing still on a Dyno! Step one - Here we relocated the MAF Meter in-front of the throttle body, this improves response and makes for a more accurate read that any tuner will see on a data logging system ex EFI Live, HP tuners etc… Step two – Here we placed the MAF meter “INSIDE” the air box with the filter to shield it from the engine heat. Step three - We created a positive seal around the perimeter of intake plenum chamber. We force feed the chamber via the front grill area by taking the natural pressure rise that occurs here and converting it to velocity via the plenum chamber. By force feeding the kit we build some pressure inside the plenum chamber which we convert to a rise in velocity in the air filter base inlet design. We confirmed its function by measuring outside temp VS actual MAF measured intake temp the result? The actual measured intake temp was consistently lower than ambient by 2-3deg F. (This design does create some ram effect but only at speed above 60mph, unlike our other proprietary ram air systems which build positive pressure in the intake manifold at speeds as low as 37MPH!) Step four - Air filter flow- in testing we found many of the Australian front mount filters either did not flow enough air to support the HP or the angles of the air box were incorrect to flow air at the highest possible VE ( volumetric efficiency) . We flow tested “ALL “of the aftermarket kits US/ Aussie on our in-house superflow flow bench all the way through the cylinder head. We flow tested with stock heads and some modified heads with flow from 248, 252 stock -378CFM on heavily modified heads - LS-2 heads as well as LS-3 & LS-7 heads. NO other aftermarket system supplied could even feed the “STOCK” heads with the proper amount of airflow they needed from .300 inches-600inches of lift@ 28inches, only the VR accomplished this and did so by a strong margin. The VR was flowed on a set of “SPECIAL” heads with a “prototype intake manifold” (more on this in spring! no comment will be made by our staff, so don’t ask) what is important is that we were able to feed the airflow required in a complete engine duty cycle on an engine that would see 700-850hp @ 7500rpm. Actual airfilter flow is between 1350 and 1800CFM @ SAE standard on anybodies flow bench even on a bad day! ( street filter vs race filter spec) Step five - delivering the flow to the filter- here we have the customer trim the upper most portion of the radiator shroud, this allows for a full 2 inches of clearance across the hood line area when the hood is closed. We measured this at a VE of 90% and came up with 1,725 CFM! (Opening the scoops showed a gain of 300CFM more at 90% VE) 2025CFM if needed! If this cut is not made it cuts flow by a staggering 50%! Which is why we say flow hood open vs. closed are separate items altogether. WE have tested; tested and tested as is the VaraRam way and we are very pleased to finally bring you this exiting new kit. THE VR Performance guarantee! |

||

| Click Here to download instruction manual | ||

(List Price: $299) |

||